Roadside assistance services operate in one of the most time-critical fields. A broken-down vehicle, a stranded driver, heavy traffic, harsh weather conditions, and high stress levels all converge at once. In the middle of this pressure, the greatest advantage a roadside assistance team can have is fast and well-organized intervention. This is exactly where an often-overlooked but decisive factor comes into play: interior shelving systems 🚐🔧

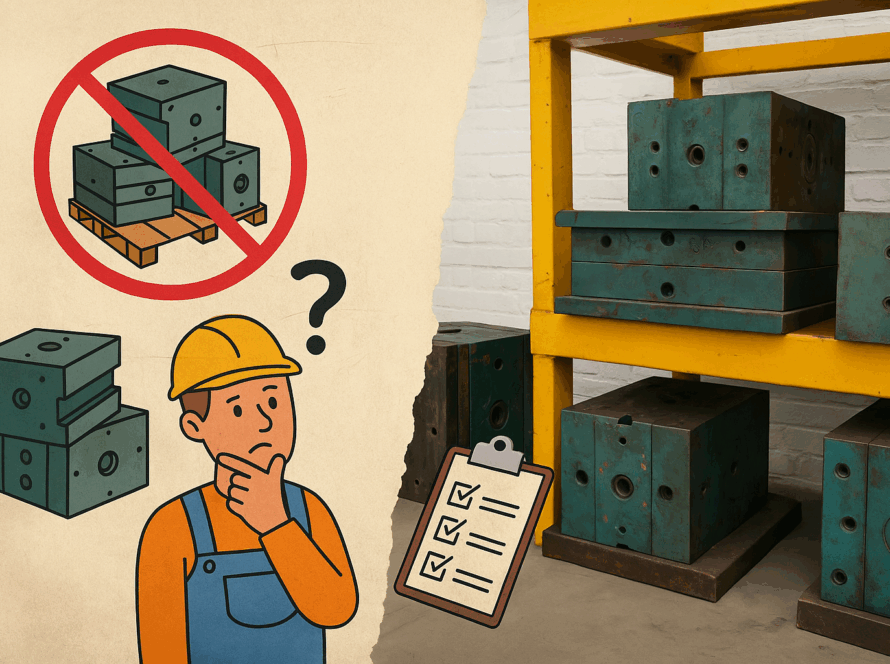

A roadside assistance vehicle is not just a tow truck or a service van; it is a mobile intervention center. Jacks, wheel chocks, cables, batteries, compressors, hand tools, warning equipment, and spare parts must all be accessible within seconds. If these items are scattered inside the vehicle, every lost minute reduces customer satisfaction and increases operational costs.

🧠 Why Are Shelving Systems So Important in Roadside Assistance Vehicles?

In roadside assistance, speed often becomes even more critical than technical expertise. Because in many cases, the issue is not complexity — it is access and organization. A well-designed shelving system allows technicians to know exactly where each piece of equipment is the moment they open the vehicle doors. This creates a smooth, almost reflexive workflow.

Studies show that organized storage systems in mobile service and roadside assistance vehicles can reduce intervention time by 25–40% on average. Data shared by Fleet Equipment Magazine highlights that proper shelving layouts significantly reduce stress levels and error rates in the field.

What truly matters is not just storing equipment, but placing the right equipment in the right location, in the right way.

⚙️ Shelving Design Principles Specific to Roadside Assistance Vehicles

1️⃣ Priority on Fast Access

Shelving systems in roadside assistance vehicles must be designed with emergency response logic, not traditional warehouse logic. The most frequently used equipment should be positioned closest to the doors and at eye level.

Typical examples include:

- Battery booster cables

- Lug wrenches

- Jacks and wheel chocks

- Warning triangles and cones

These items must be reachable in a single movement.

2️⃣ Weight and Balance Management

Roadside assistance vehicles usually carry heavy loads. Improper placement of heavy equipment negatively affects vehicle handling and safety. Heavy items should always be stored close to the floor, while lighter equipment should be placed on upper shelves.

This approach improves driving safety and extends the lifespan of both the vehicle and the shelving systems.

3️⃣ Resistance to Vibration and Impact

Roadside assistance vehicles operate not only on city roads but also on shoulders, rough terrain, and damaged surfaces. For this reason, shelving systems must include vibration-dampening mounts, lockable drawers, and secure fixing mechanisms.

🛠️ Types of Shelving Systems Used in Roadside Assistance Vehicles

| Shelving System Type | Intended Use | Advantages |

|---|---|---|

| Drawer-Based Systems 🔧 | Hand tools, small components | Fast access, high organization |

| Open Shelf Modules 📦 | Jacks, chocks, chains | Easy visual access |

| Enclosed Cabinets 🔒 | Electronic devices, sensitive equipment | Protection from dust and impact |

| Battery & Power Unit Racks 🔋 | Batteries, inverters, power supplies | Safe and stable mounting |

| Side Door Shelves 🚪 | Emergency response equipment | Significant time savings |

| Underfloor Storage 🛞 | Heavy or rarely used equipment | Improved center-of-gravity control |

The right combination of these systems transforms a roadside assistance vehicle from a chaotic storage space into a professional response unit.

⚡ Smart Storage Solutions for Faster Intervention

In recent years, smart shelving systems have gained popularity in roadside assistance vehicles. Equipment fitted with RFID tags automatically reports missing items, ensuring that vehicles are always fully equipped before deployment.

Additionally, color-coded drawers and shelves significantly improve reaction time, especially during nighttime operations. For example: red for safety equipment, yellow for electrical tools, blue for mechanical tools. This simple yet effective system allows technicians to reach the correct equipment instinctively ⏱️

🧠 A Short Anecdote: Minutes Gained Through Organization

A roadside assistance company previously spent an average of 18 minutes on a single tire change. After upgrading to modular shelving and reorganizing the vehicle interior, this time dropped to 11 minutes. With an average of 10 service calls per day, that meant a net time saving of 70 minutes daily.

In roadside assistance, 70 minutes can mean serving one or even two additional customers.

📊 Fast Roadside Assistance Workflow

Proper Shelving System

↓

Fast Equipment Access

↓

Shorter Intervention Time

↓

More Service Calls

↓

Higher Customer Satisfaction

This flow clearly demonstrates why shelving systems are not just equipment, but a strategic investment 🔁

🧭 Conclusion: Order in Roadside Assistance Means Speed and Safety

Shelving systems for roadside assistance vehicles are not an aesthetic choice — they are an operational necessity. A well-planned interior layout reduces technician stress, shortens response times, and builds customer trust.

From the Detay Endüstri perspective, well-designed shelving systems do more than carry equipment — they carry service quality. Because in roadside assistance, the difference is often not who is the fastest, but who is the most organized.

❓ Frequently Asked Questions

1️⃣ Are shelving systems for roadside assistance vehicles standardized?

No, they are custom-designed based on vehicle model and service scope.

2️⃣ Which material is more suitable?

Aluminum stands out for its light weight; steel is preferred for heavy-duty use.

3️⃣ Do shelving systems damage the vehicle?

No — professional installation actually helps protect vehicle longevity.

4️⃣ Does vibration damage shelves?

Vibration-dampening mounts significantly minimize this risk.

5️⃣ Are there special solutions for nighttime interventions?

Yes, LED-lit shelves and color coding are highly effective.

6️⃣ Do shelving systems affect fuel consumption?

Balanced load distribution improves fuel efficiency.

7️⃣ Are modular systems expensive?

Initial investment may be higher, but long-term gains outweigh the cost.

8️⃣ What is the load capacity of shelves?

Typically between 60–150 kg, depending on design and material.

9️⃣ Are side-door shelves safe?

Yes, when lockable systems are used.

🔟 Do shelving systems affect brand image?

Absolutely. A well-organized vehicle reinforces a professional company image.

🤔 People Also Ask

🔹 What is the ideal interior layout for roadside assistance vehicles?

🔹 Do shelving systems affect vehicle warranty?

🔹 Are modular systems essential for emergency response vehicles?

🔹 How should safety equipment be positioned in roadside assistance vehicles?

🔹 Are interior shelving systems a legal requirement?

🚀 Final Thoughts

Roadside assistance vehicles are the company’s showcase on the road. Where there is order, there is trust. With the right shelving systems, roadside assistance teams work not only faster, but more controlled and more professionally. Because success in roadside assistance often starts with reaching the right tool in seconds 🔧🚐